Water softeners are ubiquitous in industrial and institutional settings. You’ve probably seen one installed in a corner or up against a wall, maybe with a pallet of salt sitting next to it. Home softeners, commercial softeners and even big multi-tank industrial softeners with central brine systems all work using the same basic process.

The Softening Process

Resin beads, which just look like tiny plastic balls, are packed together in a vessel of some sort. These beads are treated chemically by resin manufacturers to attract ions present in water. In the case of softeners, the beads attract positively charged ions such as calcium, magnesium and iron dissolved in water. These positively charged ions are called cations, which is why you’ll hear of softener resin being called “cation resin”: it’s made to attract cations.

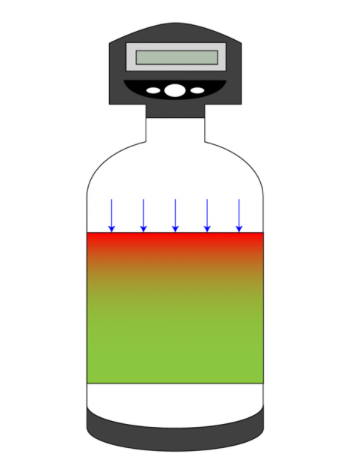

Quand les billes de résine enlèvent des cations de l’eau passant dans le réservoir, les ions qui viennent se coller aux billes prennent la place d’ions moins fortement chargés. Dans le cas d’un adoucisseur commun, les billes relâchent des ions de sodium et attirent le magnésium, le calcium, le fer et les autres cations plus fortement chargés. Dès qu’une bille n’a plus de sodium à donner, elle est épuisée.

Resin exhausts from top to bottom, creating a “transition zone”

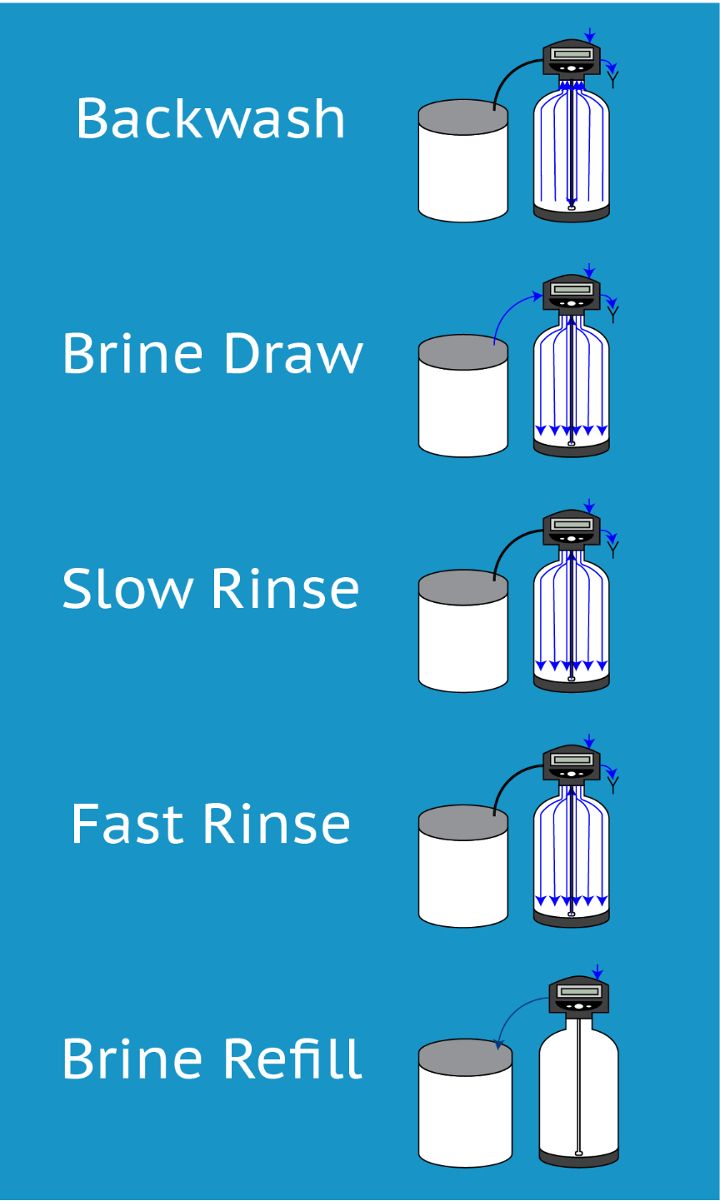

During regeneration, water no longer flows through the softener to the outlet. Rather, the system goes through a multi-step process to get the resin back to its initial sodium-loaded form. It does this in five key steps.

The Regeneration Process

Les 5 étapes de la régénération d’un adoucisseur standard

Backwash

In this step, water flows backwards (usually upwards) through the resin bed in order to help flush out any suspended solids trapped in the resin bed. In many industrial systems, a controlled flow rate is critical during this phase to prevent resin loss. Some softener systems, especially those operating on very clean water, are programmed without a backwash cycle.

Brine Draw

During brine draw, brine is drawn (by venturi) or pumped into the softener and begins flowing slowly through the resin bed. Brine concentration and flow rate are critical here. Concentrated brine may or may not be observed at the drain near the end of this phase.

Slow Rinse or Brine Displacement

During this phase, water flows into the softener and slowly displaces the brine. During this phase, brine concentration can be measured at the drain. Typically, the brine draw and slow rinse phases are programmed such that high concentration brine is measured for at least 30 minutes at the drain.

Fast Rinse

The fast rinse phase flushes the resin bed with water in order to flush out any remaining brine. This phase is typically run only on time, but conductivity measurements can be useful for reducing water consumption.

Brine refill

This is when the softener refills its brine tank, almost always with soft water. Smaller softener systems typically refill the brine tank through the same tube they use to draw brine while larger systems sometimes have a large, central brine system with its own water source.

Conclusion

Softeners come in a wide range of sizes and configurations but the basic principles by which they operate remain the same. Whether you’re looking at a small 8” diameter softener or a massive industrial system with vessels you can stand in, you can rest assured that the resin inside is removing hardness in exchange for sodium and that the system will run brine through the resin to regenerate it at some point.